Welcome to the SunGift solar panel-opedia, your one-stop-shop for all things solar PV.

We’ll be winding our time machines back a couple of centuries to the discovery of the photovoltaic effect in 1839. Our journey will begin with a leisurely stroll through the late 1800s as scientists began to scratch the surface of the world of solar. By the 1950s we’ll pick the pace up to a light jog, so bring your water bottle and a towel. Finally, you’ll want to fasten your seatbelt in preparation for the rapid acceleration of solar PV in the 21st century, mainly caused by German subsidies and Chinese policy.

The birth of photovoltaics

It all began in 1839 with a young French scientist named Alexandre Edmond Becquerel. He discovered that shining a light onto metal electrodes submerged in a conductive solution would create an electric current. He had managed to generate electricity from sunlight, the first step towards solar PV as we know it today.

The next important development came in 1873 from Willoughby Smith, an English electrical engineer. Smith stumbled upon the next piece of the puzzle when he was working on underwater telegraph wires. He was using metal bars made from the element selenium to test his underwater cables when he noticed that when exposed to sunlight, the conductivity of the selenium bars rose significantly.

Professor William Grylls Adams and his student Richard Evans Day continued the investigation into selenium into the late 1870s. In their lab in Kings College, England, they exposed Smith’s selenium bars to a candle flame at very close range. They measured an electric current in the selenium which vanished immediately when a screen was placed between the flame and the selenium, proving that it was the light, not the heat, generating the electricity.

In 1883, on the other side of the Atlantic Ocean, an American called Charles Fritts created the first solar PV cell. Fritts coated a thin layer of selenium onto a metal plate, then coated that selenium with a thin layer of gold-leaf film. He observed the resulting electric current not only when subject to direct sunlight, but also in dim light conditions. Whilst the world was impressed by the concept, with an efficiency of less than 1%, these cells were hardly the finished product.

The 20th century would see continued advances in photovoltaics. In 1905 Albert Einstein – finally a name we recognise! – developed a theory of light that explained the photovoltaic findings of the 1800s. Einstein broke light down into packets of energy – we now refer to these packets as photons or light particles. Combined with the discovery of electrons, a proper understanding of the photovoltaic effect began to materialise. When a photon strikes a semiconductor material – like selenium – it has enough energy to knock an electron out of its orbit around its atom. If the material is connected to an electrical circuit, the electron can flow around the circuit and transfer its energy.

So far the cost and inefficiency of photovoltaics using gold-coated selenium was impeding the eventual commercialisation of solar PV. Fritts optimistically claimed that his invention could compete with Thomas Edison’s coal-fired power plants. To make Fritts’ dream come true we would need something cheaper and more abundant than selenium.

The crack in the silicon

In 1940 something very important happened at Bell Labs in New Jersey, USA. Russell Shoemaker Ohl was experimenting with some silicon samples, one of which has a crack running through it. When exposed to light, he measured an electric current in this sample.

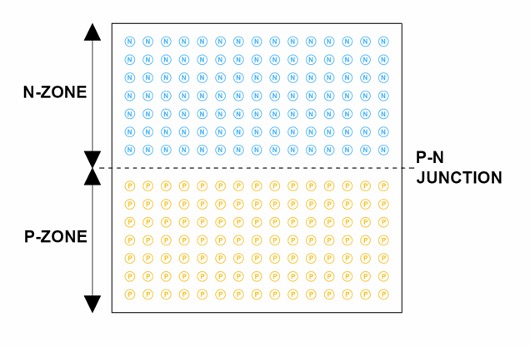

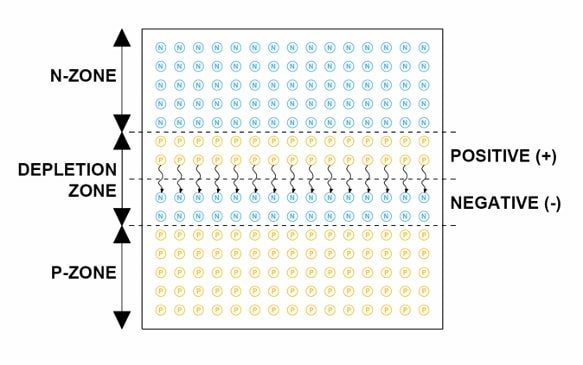

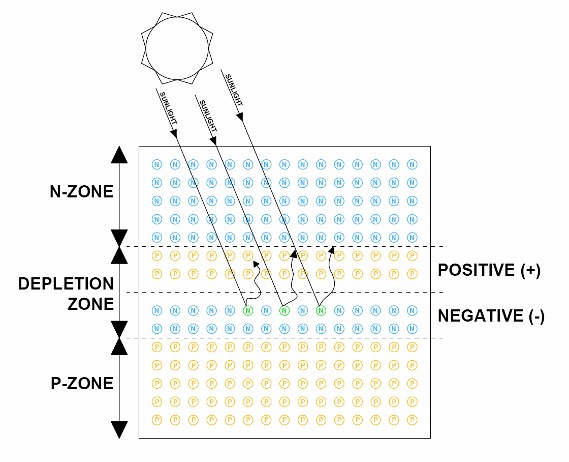

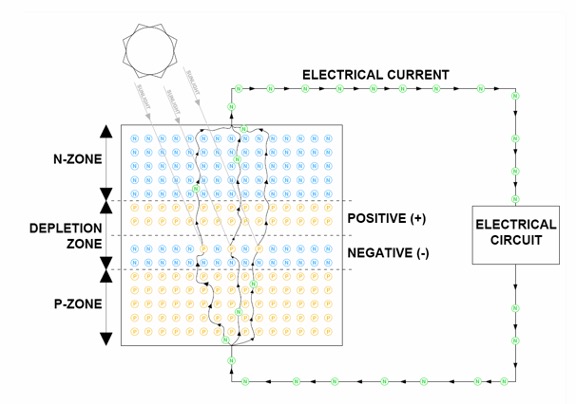

So, why is the crack so important? The crack in the silicon acted as a separator between two regions of silicon with different levels of impurity. On one side the silicon was negatively doped (each silicon atom had a spare electron*, we call this the N-zone) whereas the other side was positively doped (each silicon atom had a spare hole for an electron to fill, we call this the P-zone). The crack created what we now call a P-N junction. At the junction, some of the spare electrons from the N-zone move across the crack and fill the spare holes in the silicon atoms in the P-zone, creating what is called a ‘depletion zone’ at the junction.

*What is an electron? Electrons are tiny, negatively charged, particles that make up part of atoms. When electrons flow around an electrical circuit we have a useful electrical current.

On one side of the depletion zone there is a positive charge due to the lack of electrons whereas the other side is negatively charged, due to the extra electrons. This creates an electric field across the zone. When sunlight hits the P-N junction, as Einstein described, the light photon would energise the electrons in the depletion zone, knocking them out of their holes. Due to the electric field, the freed electrons are drawn back towards the N-zone. All Ohl had to do was hook each side of the silicon up to a circuit and the loose electrons would start to flow, generating a useful electric current.

Ohl’s first solar cell was still only about 1% efficient at turning the sun’s energy into useful electricity. However, it was still a huge breakthrough. Not only is silicon about 15 times more efficient than selenium, it is also extremely abundant and cheap. These two qualities were essential for the solar revolution to happen.

1954 saw another breakthrough for the guys at Bell Labs. They had identified several ways to engineer the properties of the silicon cells to make them more efficient. One major change was the use of boron and arsenic on either side of the P-N junction, changing the level of impurity and therefore the ability of the silicon to convert sunlight to electricity. They also made sure that the P-N junction stayed near the surface of the silicon, closest to the incoming light and made significant improvements to the electrical contacts with the silicon cells (the inter-cell connectors that allow the electrons to flow in and out of the silicon). Not satisfied with just the one cell, they linked a few cells together, making the world’s first solar ‘panel’ or ‘module’. The combination of all these improvements was a solar panel that converted 6% of incoming sunlight into electricity, quite a leap forward from Ohl’s first cell 14 years earlier.

So far, solar PV has existed almost exclusively in laboratories. When would we actually start using it for something useful? The gold medal goes to Charles Fritts. He used his gold-coated selenium cells to build the world’s first rooftop array in New York City in 1884. However, due to the high cost and low efficiencies, it didn’t catch on. After the research into silicon by Bell Labs, the landscape changed as investors were drawn to a much more promising technology. One of the early adopters of solar PV was the US government, who decided to use solar PV cells to power the Vanguard 1 satellite in 1958. Decisions like this enabled further research and development into solar cells, driving forward increased efficiencies at lower and lower costs.

German policy and Chinese opportunity

Most solar panels are made in Asia. Some people may see this as a negative. We remember the little ‘made in China’ sticker on some of our consumer electronics and associate it with low quality. When it comes to solar PV, we should be thinking the absolute opposite.

Which country do we associate with making the best pizzas, chocolate or maple syrup? Most people will answer Italy, Belgium and Canada, respectively. If you want to eat the best pizza in the world, you go to Italy, simple as that. In the world of solar PV, if you want to buy the best solar panels, you go to Asia. Here’s why.

So, why is Asia the centre of the solar Universe? Some of the credit goes to the German government of the 1990s.

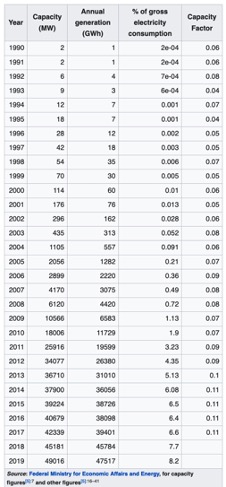

It all began on 1st January 1991 with the introduction of the ‘Stromeinspeisungsgesetz’ (or ‘Electricity Feed-in Act’ to non-German speakers). Much to the benefit of the rest of the world, Germany were the feed-in-tariff guinea pig. The Electricity Feed-in Tariff was the first of its kind in the world, so it was bound to be far from perfect. Luckily the Germans persisted, smoothed out the bumps and on 1st April 2000, replaced it with the Renewable Energy Sources Act (also known as the EEG). The EEG was amended several times as the years went by, the most significant of which came in 2004, increasing the tariff rates. Interested in the emerging solar markets, countries such as Spain and Italy jumped on the bandwagon and too introduced early Feed-in-Tariffs.

Another significant milestone came one year later in 2005, when our very own SunGift Solar was founded by director Gabriel Wondrausch. As a company we’ve grown with the industry from its teenage years in 2005, through a rollercoaster of a market, full of unpredictable government subsidies and rapidly developing solar panel efficiencies, to the now subsidy-free solar landscape and panel power outputs topping 400W.

Source – https://en.wikipedia.org/wiki/Solar_power_in_Germany

Europe was hungry for solar, but who was going to make all the panels? This is where China joins the party.

Intrigued by the surge in demand for solar in Europe, China began to ramp up its manufacturing. From sourcing vast amounts of silicon to building huge automated factories and hiring photovoltaic experts, China were all-in on solar. The Chinese government even offered tax credits to solar manufacturers, encouraging foreign companies to make the move to China. The workforce here was skilled and cheap, making it an opportunity too good to miss. As momentum grew, Chinese companies began to buy their European counterparts, removing their competition from the game entirely. Nowadays there really are a very small number of PV manufacturers left outside of Asia. The survivors struggle to compete on price and quality with the Chinese manufacturers due to the sheer scale of the operation. There are still very good solar cell manufacturers outside of China, making high quality traditional PV cells and also feeding the lower volume demand for building-integrated solar.

The Learning Curve

The Chinese solar industry kept on growing and growing and as a result their factories became more and more efficient. This meant that panel prices became cheaper and cheaper whilst the panels themselves became more and more powerful. There is a phenomenon to describe what happened (and is still happening) to solar PV manufacturing. It’s called the ‘learning curve’.

Imagine you are faced with building a bit of flat-pack furniture from IKEA. You have a manual and all the tools, but because you are doing it for the first time, it still takes a lot of head-scratching and obscenities before you finish the job 2 hours later. Now you’ve done it once, how long would it take you to build the exact same piece of furniture? Probably quite a lot less time. Everything you learnt from the first build can be applied to the new build, so you will make fewer mistakes and do a faster job to a higher quality finish. Now let’s say you build 100 of the same bits of furniture. I would bet that the 100th build would take you no more than 15 minutes.

The learning curve mainly deals with two parameters. Firstly there is the total output – in solar PV terms this is the cumulative total of worldwide solar manufacturing. Then there is the cost reduction – how much it costs to manufacture the solar cells. As the total output goes up, the manufacturing cost goes down. These two metrics are related in different ways for different products. For solar PV cells, each time the total output of solar cells double, the cost falls by over 20%. This is important because of how quickly solar cell production is increasing. In the mid 1970s solar cell manufacturing cost about $100 per Watt, but by 2016 this had fallen to $0.5. The demand only really began in the mid 00’s and it’s only 2020 now. Many people think that if the solar learning curve continues, then solar will dominate the world energy market much sooner than predicted.

Conclusion

Sorry folks but the time machine has reached its final stop, 2020. Time to get off – we hope you enjoyed the ride. Next time you see a solar panel, stop and think back to Becquerel, Smith, Adams, Fritz, Ohl and all those who dedicated hours and years into the early stages of the learning curve. Without them we wouldn’t have the high-efficiency, low-cost solar that we have today. Their early innovation paved the way for a future powered by the sun.

Solar PV Contractor of the Year 2024

Solar PV Contractor of the Year 2024